Description

Estimated time: 0.50 hours

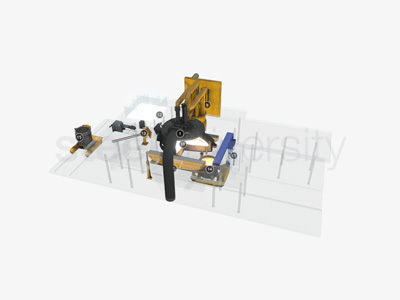

Electric Arc Furnaces (EAFs) are used to produce carbon steels and alloy steels primarily by recycling ferrous scrap. In an EAF, scrap and/or manufactured iron– such as DRI, pig iron, iron carbide – units are melted and converted into high quality steel by using high-power electric arcs formed between a cathode and one (for DC) or three (for AC) anodes. An electric current is passed through the electrodes to form an arc. The heat generated by this arc melts the scrap. The electricity needed for this process is enough to power a town with a population of 100,000. During the melting process, other metals (ferro-alloys) are added to the steel to give it the required chemical composition.

Scrap is by far the most important resource, accounting for about 80% of all electric arc furnace metal feedstock. The modern electric arc furnace typically makes 150 tonnes in each melt, which takes around 90 minutes.

Course Content