Description

Estimated time: 8 hours

Language: English

Modality: Virtual.

Summary of the course

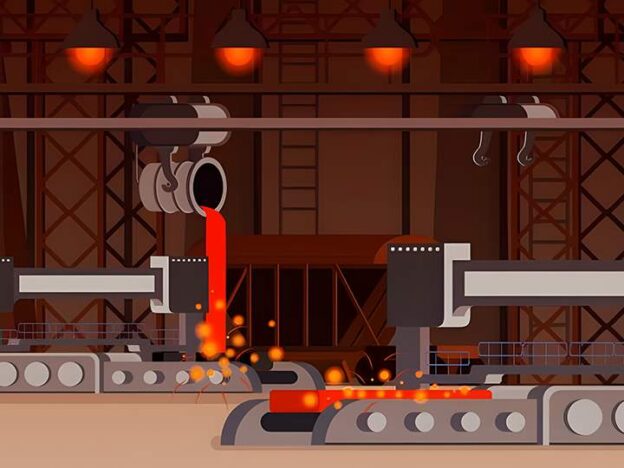

Iron ore as mined is a combination of iron with oxygen and numerous other unwanted substances, generally known as “gangue”. The process of reducing iron ore to metallic iron is known as Iron Making. This process is carried out in a blast furnace, using coke as both a fuel and reducing agent.

The Iron-making e-learning module from Tata Steel Digie-Shala brings forth an in-depth overview of the blast furnace process and raw materials considerations. This module is a combination of theoretical and operational aspects. The course is aimed at people who are either looking to build their career in the steel industry or working in it, as well as the iron & steel supply chain. Students will benefit from a broad understanding of the iron-making process.

By the end of this module you will be able to understand:-

1. Raw materials involved in the process of Iron Making

2. History and some important facts of Iron Ore

3. Operations of Blast Furnace and its significance

4. Slag Formation process

5. Alternate processes or routes of Iron-making

Official Certificate from steeluniversity

Receive a digital certificate signed by steeluniversity and worldsteel directors with the institution’s logo to verify your achievement.

Increase job prospects

worldsteel represents over 160 steel producers, national and regional steel industry associations, and steel research institutes. With a certificate from steeluniversity / worldsteel you can improve your CV to work for the steel industry.

Course Content