Description

Estimated time: 3 hours

Language: English

Modality: Virtual.

Summary of the course

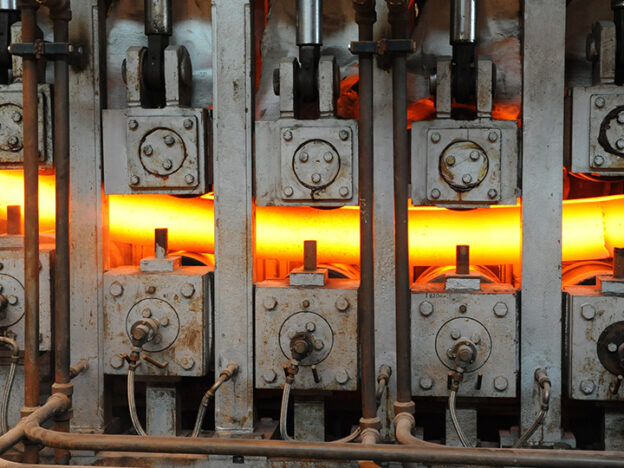

These lectures outlines the areas on a continuous casting plant where caster instrumentation can improve the process control.

It considers how improved process control will produce better quality cast steel, in-turn reducing defects, increasing yield and production.

Learning outcomes:

– By taking this course you will learn how the caster instrumentation has improved the caster capability, product yield and quality of continuously cast product by:

– Improving the flow of steel in the ladle and tundish area

– Monitoring thermal conditions in the mould

– Continuously monitoring and controlling in-mould conditions

– Reviewing mould oscillations and width and taper control

– Maintaining the correct cooling and support in the strand guides

– Determining slab dimensions and inspecting the slab surface

Official Certificate from steeluniversity

Receive a digital certificate signed by steeluniversity and worldsteel directors with the institution’s logo to verify your achievement.

Increase job prospects

worldsteel represents over 160 steel producers, national and regional steel industry associations, and steel research institutes. With a certificate from steeluniversity / worldsteel you can improve your CV to work for the steel industry.